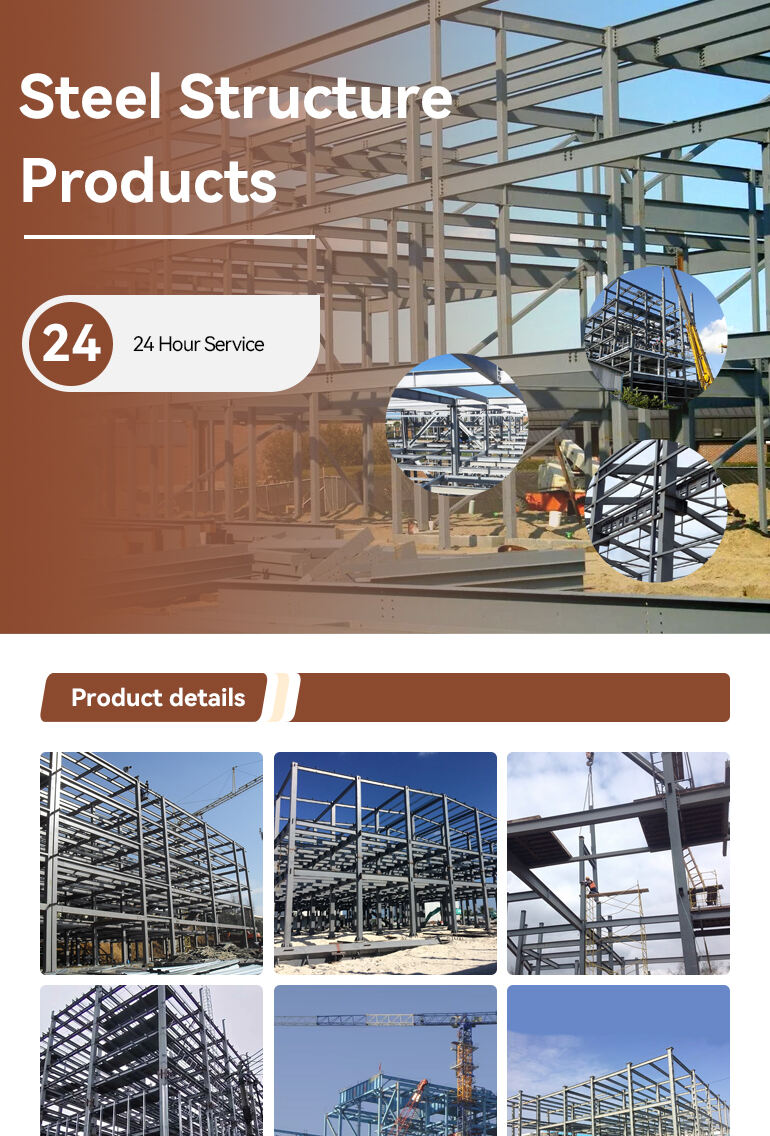

Steel structure building is a kind of building form with steel as the main structural material, which has the characteristics of high strength, light weight, fast construction speed and good earthquake resistance. It is widely used in many scenes such as industrial plants, commercial buildings, gymnasiums, bridges, high-rise residential buildings, etc.

Steel structure building is a building form with steel as the main structural material, which has the characteristics of high strength, light weight, fast construction speed and good earthquake resistance. It is widely used in industrial plants, commercial buildings, gymnasiums, bridges, high-rise residential buildings and other scenarios.

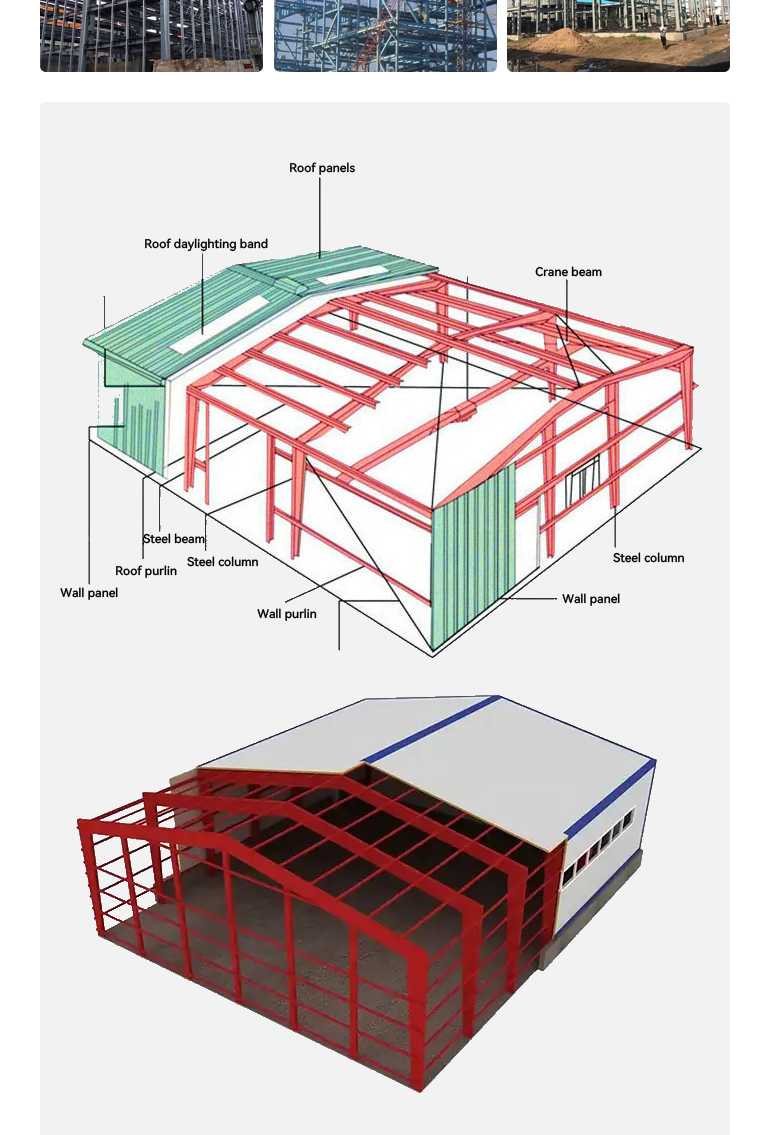

Main features:

High strength and light weight: Steel has high strength and good ductility, can withstand large loads, and the structure has a light weight, which can reduce the foundation cost.

Fast construction speed: Steel structure components are usually prefabricated in factories, and on-site installation is convenient, which greatly shortens the construction period.

Good earthquake resistance: The ductility of steel enables it to effectively dissipate energy and reduce structural damage under the action of earthquakes.

Recyclable: Steel can be recycled many times, meet environmental protection requirements, and reduce the generation of construction waste.

Flexible design: Various shapes and sizes can be customized according to building needs to meet diverse design requirements.

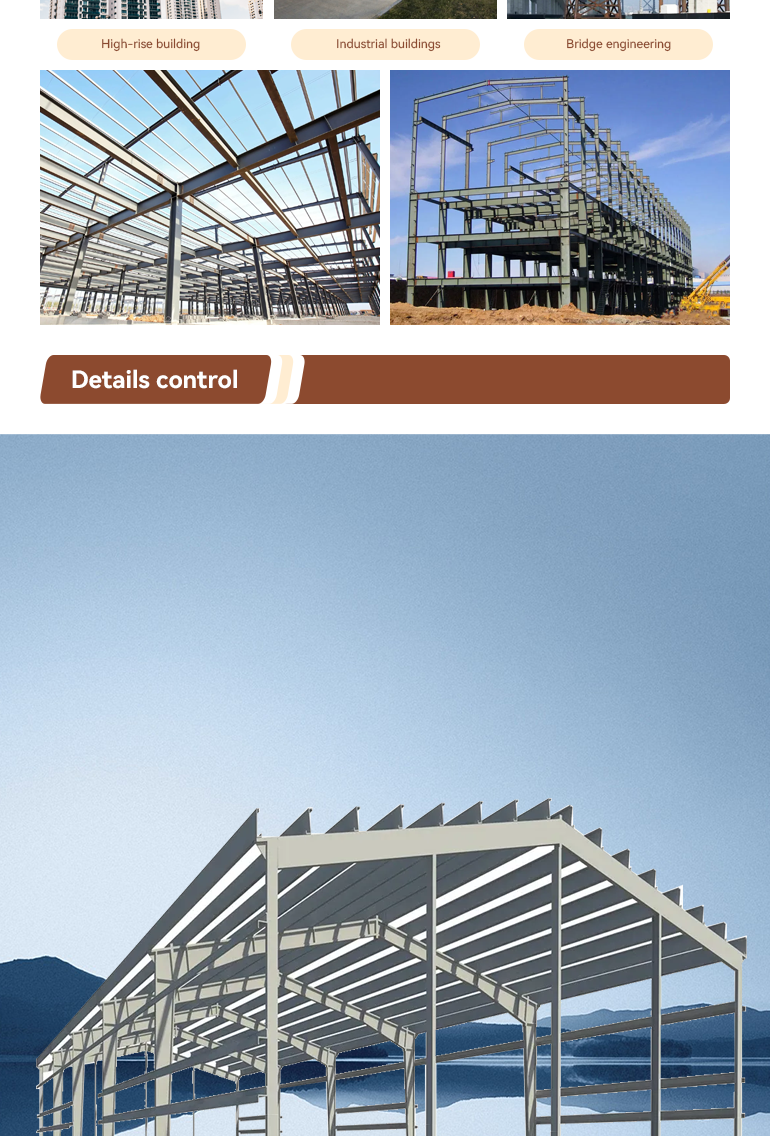

Application scenarios:

Industrial plant: Suitable for production workshops with large spans and large spaces, convenient for equipment installation and material transportation.

Commercial buildings: such as shopping centers and supermarkets, which can realize large column-free spaces and improve the utilization rate of commercial spaces.

Stadiums: Suitable for large-span buildings such as gymnasiums and swimming pools to meet the space requirements of large-scale activities.

High-rise residential buildings: Steel-structured high-rise residential buildings have the advantages of fast construction speed and good earthquake resistance.

Bridge engineering: Steel-structured bridges are easy to construct and can be built quickly, reducing traffic interruption time.

Development trend:

With the advancement of technology and the enhancement of environmental awareness, steel-structured buildings have shown broad development prospects in the fields of green buildings and prefabricated buildings. It can not only improve building quality and construction efficiency, but also effectively reduce the impact of buildings on the environment.

Steel-structured buildings, with their unique advantages, are gradually becoming one of the important choices for modern buildings.

| Parameter Category | Parameter name | Unit | Parameter Value | Remark |

| Material properties | Steel grade | - |

Q235 |

Commonly used building structural steel with good welding performance and toughness |

| Yield Strength | MPa |

235 |

||

| Tensile strength | MPa |

370-500 |

||

| Elongation | % |

≥22 |

||

| Cross-section | Section Type | - |

H-Type | Hot rolled H-beam, suitable for beam and column components |

| Cross-section size | mm |

300×300×10×15 |

Height × width × web thickness × flange thickness | |

| Component size | Component length | mm |

9000 |

Determined by nominal length |

| Surface treatment | Anti-corrosion coating | - |

Thermosetting epoxy resin electrostatic spraying | Durability more than 10 years |

| Corrosion resistance grade | - |

Sa2.5 |

Sand Derusting Grade | |

| Connection | Welding methods | - |

Manual welding/automatic welding | The weld quality must comply with GB 50661 |

Bolted connections |

- |

High Strength Bolts | The preload force is determined according to the bolt specifications. | |

| Other parameters | Slenderness ratio | - |

≤150 |

Allowable slenderness ratio of tension members |

| Allowable deflection | - |

Beam deflection does not exceed L/300 | L is the span of the beam |